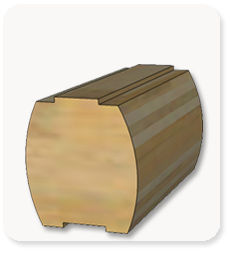

Our House Log

Production

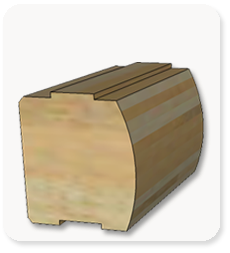

We believe we have the best house logs on the market and take extreme care in producing them.

When logs dry, it is necessary for the core of the log

to dry as well as the outside. Normally, when this happens,

the logs check (crack). To control this checking, our logs are given

a special 'kerf' cut which allows the core to dry at the same rate as the

shell. The result? Very little checking and virtually no shrinkage.

Also, in order to conserve the natural house log look, we provide a foam filler that can be applied